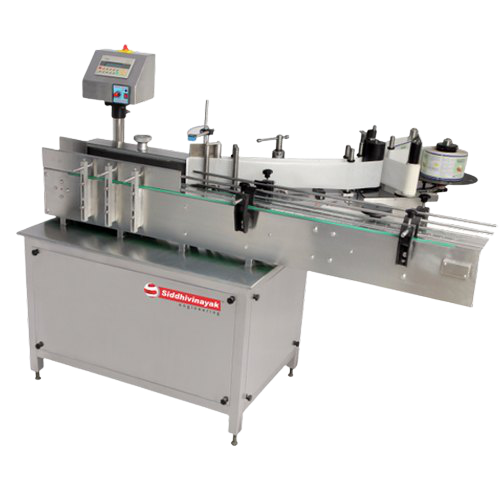

Automatic Volumetric Liquid Filling Machine

Automatic Volumetric liquid filling machine that has the best performance for Semi Viscous & Less Viscous liquid. Volumetric liquid filling machine is a type of industrial machine used to accurately Automatic Volumetric liquid filling machine that has the best performance for Semi Viscous & Less Viscous liquid. Volumetric liquid filling machine is a type of industrial machine used to accurately Automatic Volumetric liquid filling machine that has the best performance for Semi Viscous & Less Viscous liquid. Volumetric liquid filling machine is a type of industrial machine used to accurately Automatic Volumetric liquid filling machine that has the best performance for Semi Viscous & Less Viscous liquid. Volumetric liquid filling machine is a type of industrial machine used to accurately Automatic Volumetric liquid filling machine that has the best performance for Semi Viscous & Less Viscous liquid. Volumetric liquid filling machine is a type of industrial machine used to accurately Automatic Volumetric liquid filling machine that has the best performance for Semi Viscous & Less Viscous liquid. Volumetric liquid filling machine is a type of industrial machine used to accurately

No Bottle

No Filling

100% Spillage

Drip Free

Minimum Change

Over time

Partially guarding

for safety

Model

SVVLF 100

Direction Off Movement

Left to Right

Output/Min*

Up to 30 BPM

Power Supply

2.0 kW Single Phase 220 Volts / 50 Hz (Can Customized as Client Need)

Moc

Stainless Steel 304, Anodized Aluminum

Machine Dimention

L 2000 mm * W 800 mm * H 1700 mm (+/- 50mm )

Convayer Length

L 2000 mm * W 100 mm Slat Chain

No. of Head

4 Head

Filling System

Mechaniacally operated Piston cylinder

Machine Motion

Linear

Suitable for Products

Free Flowing Liquids

Filling Range

50ml to 1000 ml

Volume Adjustment

Adj. of Volume Block screw

Suck back System

Non Return Valve (NRV) Based

Filling Nozzel

Bottom to top Pneuamatically Driving Nozzel System

Filling Volume Accuracy

+/-1 % (depending upon type of liquid )

Air Supply

2 CFM with 4-6 bar pressure with filter and regulator

Suitable for Packing Material

HDPE / PET / GLASS / METAL TIN / Aluminum Bottles

Machine Weight (kg)

450 kg

Model

SVVLF 150

Direction Off Movement

Left to Right

Output/Min*

Up to 30 BPM

Power Supply

2.0 kW Single Phase 220 Volts / 50 Hz (Can Customized as Client Need)

Moc

Stainless Steel 304, Anodized Aluminum

Machine Dimention

L 2000 mm * W 800 mm * H 1700 mm (+/- 50mm )

Convayer Length

L 2000 mm * W 100 mm Slat Chain

No. of Head

4 Head

Filling System

Mechaniacally operated Piston cylinder

Machine Motion

Linear

Suitable for Products

Free Flowing Liquids

Filling Range

50ml to 1000 ml

Volume Adjustment

Adj. of Volume Block screw

Suck back System

Non Return Valve (NRV) Based

Filling Nozzel

Bottom to top Pneuamatically Driving Nozzel System

Filling Volume Accuracy

+/-1 % (depending upon type of liquid )

Air Supply

2 CFM with 4-6 bar pressure with filter and regulator

Suitable for Packing Material

HDPE / PET / GLASS / METAL TIN / Aluminum Bottles

Machine Weight (kg)

450 kg

Model

SVVLF 200

Direction Off Movement

Left to Right

Output/Min*

Up to 30 BPM

Power Supply

2.0 kW Single Phase 220 Volts / 50 Hz (Can Customized as Client Need)

Moc

Stainless Steel 304, Anodized Aluminum

Machine Dimention

L 2000 mm * W 800 mm * H 1700 mm (+/- 50mm )

Convayer Length

L 2000 mm * W 100 mm Slat Chain

No. of Head

4 Head

Filling System

Mechaniacally operated Piston cylinder

Machine Motion

Linear

Suitable for Products

Free Flowing Liquids

Filling Range

50ml to 1000 ml

Volume Adjustment

Adj. of Volume Block screw

Suck back System

Non Return Valve (NRV) Based

Filling Nozzel

Bottom to top Pneuamatically Driving Nozzel System

Filling Volume Accuracy

+/-1 % (depending upon type of liquid )

Air Supply

2 CFM with 4-6 bar pressure with filter and regulator

Suitable for Packing Material

HDPE / PET / GLASS / METAL TIN / Aluminum Bottles

Machine Weight (kg)

450 kg

Part Name

Make

Description

Convayer Motor

Born Vario

0.18 kW Motor with reduction gear box

Machine Gear Box With Motor

Born Vario

1.0 kW Gear Box with Motor

Speed Controller Drive

Allen Bradly / Danfoss

Variable Frequency Drive

Sensor

Wanglore / Leuze

Diffuse type Sensor

Part Name

Make

Description

Convayer Motor

Born Vario

0.18 kW Motor with reduction gear box

Machine Gear Box With Motor

Born Vario

1.0 kW Gear Box with Motor

Speed Controller Drive

Allen Bradly / Danfoss

Variable Frequency Drive

Sensor

Wanglore / Leuze

Diffuse type Sensor

Part Name

Make

Description

Convayer Motor

Born Vario

0.18 kW Motor with reduction gear box

Machine Gear Box With Motor

Born Vario

1.0 kW Gear Box with Motor

Speed Controller Drive

Allen Bradly / Danfoss

Variable Frequency Drive

Sensor

Wanglore / Leuze

Diffuse type Sensor

No Bottle No Filling

No Bottle - Machine Stop System

Construction inlucding base frame structure of SS 304 anodized aluminium to ensures durability

Precisely design Piston for accureate filling operation.

Measuring scale with pointer indication on Volume setting screw-Easy Change Over.

Bottle holding mechanism for the best position of the bottles before filling action.

Diving Nozzle to reduce bubbling of foamy liquids

Adjustable conveyor guide rails to accommodate with different products

Designed for easy changeover and cleaning.

Minimum Change Over time

Synchronized variable speed control

100% spillage/drip free

All contact parts are SS-316/peek/PTFE/Teflon/Silicon and non-contact parts SS 304

CIP without open any part at temperatures up to 70°c

Individual fill volume adjustment for fine tuning

Partially guarding for safety

Safety Cabinet

To get more hygienic environment and ensure safety & quality use safety cabinet

Dropping Tray under the Nozzles

Pneumatic Operated Drooping Tray under the Nozzles for High viscussed liquid

Boottle Neck Holding Guide

Bottle neck holding mechanism for the best position of the bottles before filling action.

Capacity for additional Fill Heads

Provision of additonal head mouting space to set additional filling Head in futrure.

Safety Cabinet

To get more hygienic environment and ensure safety & quality use safety cabinet

Flame Proof System

Provide Flame proof control panel wtih flame proof electrical and electronics devices for flammble filling material

Main Components of Machine

Product Conveyor

Bottle Stopper assembly

Nozzle Driving system

Storage Tank

Inlet Valve

Display with Panel

Anti Drip Nozzle

Main Control Panel

Product Conveyor

S.S. 304 slat chain conveyor . To Convey the container smoothly.

Bottle Stopper assembly

Air - Pneumatically Operated Stopper. Hold the Bottle at Filling Station

Nozzle Driving system

Air - Pneumatically Operated diving Nozzles assembly. Bottom to Top bottle filling to reduce bubbling of foamy liquids

Storage Tank

Consist of S.S. 304/ S.S.316 grade. To provide sufficient storage capacity for uninrupted filling operation

Inlet Valve

Electromagnetic Solenoid Inlet Valve & potential contact free liquid level switch. Both are integrated with the PLC system which will maintained the storage tank level.

Display with Panel

Color Touch Scren HMI display. Easy access of machine

Anti Drip Nozzle

Pneumatic operated nozzle shut off valve to prevent dropping and keep clean surface of bottle & conveyer.

Main Control Panel

Dust proof Control panel having necessary panel protection.

Applications

Add Your Heading Text Here

Siddhivinayak Industries is offered you a complete choice of automation technology filling machines which include a volumetric liquid filling machine

Add Your Heading Text Here

Siddhivinayak Industries is offered you a complete choice of automation technology filling machines which include a volumetric liquid filling machine, Gravity filling machines, Automatic Volumetric Liquid Filling Machine, Semi-automatic Volumetric Liquid Filling Machine, Volumetric Bottle Filling Machine, Volumetric Piston Filling Machine. We have different choices available for Liquid Filling Machine such as Single Head Volumetric Liquid Filling Machine, Double Head Volumetric Liquid Filling Machine, Four Head Volumetric Liquid Filling Machine, Six Head Volumetric Liquid Filling Machine, Eight Head Volumetric Liquid Filling Machine and Multiple Head Volumetric Liquid Filling Machine.

PET

HDPE

Aluminium

Glass

Glass

Glass

Add Your Heading Text Here

Siddhivinayak Industries is offered you a complete choice of automation technology filling machines which include a volumetric liquid filling machine, Gravity filling machines, Automatic Volumetric Liquid Filling Machine, Semi-automatic Volumetric Liquid Filling Machine, Volumetric Bottle Filling Machine, Volumetric Piston Filling Machine. We have different choices available for Liquid Filling Machine such as Single Head Volumetric Liquid Filling Machine, Double Head Volumetric Liquid Filling Machine, Four Head Volumetric Liquid Filling Machine, Six Head Volumetric Liquid Filling Machine, Eight Head Volumetric Liquid Filling Machine and Multiple Head Volumetric Liquid Filling Machine.

Pharmaceutical

Beverages

Agriculture

Dairy

Chemical

Chemical

Add Your Heading Text Here

Siddhivinayak Industries is offered you a complete choice of automation technology filling machines which include a volumetric liquid filling machine, Gravity filling machines, Automatic Volumetric Liquid Filling Machine, Semi-automatic Volumetric Liquid Filling Machine, Volumetric Bottle Filling Machine, Volumetric Piston Filling Machine. We have different choices available for Liquid Filling Machine such as Single Head Volumetric Liquid Filling Machine, Double Head Volumetric Liquid Filling Machine, Four Head Volumetric Liquid Filling Machine, Six Head Volumetric Liquid Filling Machine, Eight Head Volumetric Liquid Filling Machine and Multiple Head Volumetric Liquid Filling Machine.

Syrups

Mustard

Ketchup

Dipping sauces

Shampoo

Pesticides

Water

Juice

Liquor

Filling Process

Step 1

Feed bottles on conveyor or using automatic botte turntable. The Conveyor convey the bottles very smoothly. When container moves on conveyor Product Sensor gives command to controller and Stopper system hold the 4 nos. of bottle below the filling station at right position for filling. Meanwhile all 4 sets of Piston-cylinder which is mechanically coulpled with main motor through the gear will suck the liquid from exisiting tank through Hose pipe

Step 1

Step 2

The Driving Nozzles unit comes downward and nozzles entering in to the bottle and filling will start.diving nozzle will moves upward till filling completed.

Step 2

Step 3

When filling start, driving nozzle parallaly moves upward till filling completed and Bottle Stopper will open and bottles moves out from the filling statiion.

Step 3

Step 4

Then the bottle goes to the next processing.

Step 4

FAQs

We have a wide range of Filling machines such as Automatic Volumetric Liquid Filling Machine, Semi-automatic Volumetric Liquid Filling Machine, Volumetric Piston Filling Machine, Volumetric powder filling machine, Gravimetric Filling Machine, Volumetric Liquid Bottle Filling Machine, Single Head Volumetric Filling Machine, Multi Head Volumetric Filling Machine & more.

A liquid filling machine can fill a wide variety of liquid products, including beverages (water, juice, energy drinks, etc.), edible oils, pharmaceutical solutions, chemical solutions, cleaning liquids, personal care products (shampoo, lotion, etc.), and many others. The type of liquid product to be filled and the packaging material used will determine the specific type of liquid filling machine required

Liquid filling machines are used in a variety of industries that require liquid packaging, such as food and beverage, pharmaceuticals, cosmetics, personal care, and chemical industries. In the food and beverage industry, liquid filling machines are used to package products like water, juice, dairy, and sauces. In the pharmaceutical industry, they are used to fill medicine bottles with liquids like syrups and suspensions. Similarly, in the cosmetics and personal care industry, they are used to package products like shampoo, lotion, and liquid soap. In the chemical industry, they are used to package chemical solutions like cleaning liquids and solvents

An automatic liquid filling machine is a type of industrial machinery used to fill containers with liquids, such as water, juice, oil, or cleaning products. The machine is designed to perform the filling process automatically, with minimal human intervention, to improve efficiency and accuracy.

An automatic liquid filling machine can fill various types of containers, including bottles, jars, pouches, cans, and containers with irregular shapes. The machine can be configured to handle different container sizes, shapes, and materials, depending on the specific needs of the application

Reviews

Blogs

3. Introducing the Automatic Pneumatic Piston Liquid Filling Machine

2. Introducing the Automatic Pneumatic Piston Liquid Filling Machine

1. Introducing the Automatic Pneumatic Piston Liquid Filling Machine

International Standards Used In The Design Of Sticker Labeling Machine

International Standards Used In The Design Of liquid Filling Machine

Why Email Marketing Is Still Crucial

International Standards Used In The Design Of Ball Valves